About Industrial Engineering

Industrial engineering is concerned with the development, improvement, implementation and evaluation of integrated systems of people, knowledge, equipment, energy, material and process.

Industrial engineering draws upon the principles and methods of engineering analysis and synthesis. It eliminates waste of time, money, materials, energy and other resources. Industrial Engineering is also sometimes referred to as Operations Management, Manufacturing Systems Engineering, Engineering Management, etc. depending on the viewpoint or motives of the user.

Whereas most engineering disciplines apply skills to very specific areas, industrial engineering is applied in virtually every industry. Industrial Engineers work on projects like shortening queues at a theme park, scheduling an operating room in a hospital, distributing products worldwide, manufacturing cheaper and more reliable automobiles, etc.

Even though the term industrial engineering is originally applied to manufacturing, it has extended its scope to cover similar fields like operations research, information systems, ergonomics and quality engineering. While Industrial Engineer was originally focused on manufacturing, industrial engineers are now involved in the design of systems and processes to produce and deliver goods and services in all types of organization. We work to integrate systems involving people, materials, facilities, finances, equipment, energy, and information. Our objective is to achieve the best possible results in terms of quality, productivity, and safety.

Objectives

PROGRAMME EDUCATIONAL OBJECTIVES (PEOs):

The Programme Educational Objectives of B.Tech. (Industrial Engineering )programmes are:

- To prepare graduates who will be successful professionals in industry, government, academia, research, entrepreneurial pursuit and consulting firms

- To prepare graduates who will contribute to society as broadly educated, expressive, ethical and responsible citizens with proven expertise

- To prepare graduates who will achieve peer-recognition; as an individual or in a team; through demonstration of good analytical, design and implementation skills

- To prepare graduates who will thrive to pursue life-long learning to fulfill their goals

PROGRAMME OUTCOMES (POs):

Undergraduate engineering programmes are designed to prepare graduates to attain the following program outcomes:

- An ability to apply knowledge of mathematics, science and engineering in practice

- An ability to identify, critically analyze, formulate and solve engineering problems

- An ability to select appropriate engineering tools and techniques and use them with dexterity

- An ability to design a system and process to meet desired needs within realistic constraints such as health, safety, security and manufacturability

- An ability to devise and conduct experiments, interpret data and provide well informed conclusions

- An ability to understand the impact of engineering solutions within purview of laws, in a contemporary, global, economical, environmental, and societal context for sustainable development

- An ability to function professionally with ethical response ability as an individual as well as in multidisciplinary teams with positive attitude

- An ability to communicate effectively

- An ability to appreciate the importance of goal setting and to recognize the need for life-long learning

- To produce well informed socially responsible global citizen with sharp critical thinking skills having sound awareness about finance management, engineering laws and human rights, ethics and values. They will have entrepreneurial spirit.

History

Department of Industrial Engineering started its journey on 2011 with an inaugural batch of 60 students admitted for B. Tech course in Industrial Engineering. The department presently houses more than 200 students pursuing their Undergraduate and Doctoral Degrees. The department is equipped with state of art laboratories for carrying out world class research. The first batch of Industrial Engineering students graduated with B. Tech. degrees in 2015.

Head of the department

Dr. D M Parikh

Dean FoET & Head

Department of Industrial Engineering

Dr. D M Parikh completed his Bachelor of Engineering in Mechanical with distinction from one the premier college in Gujarat Acquired M. Tech from Indian Institute of Technology (KGP) in Industrial Management. Did research on the topic of “Study of Development of Financial Intermediation on account of Economical Development for the post libeberalization era through Multivariate Relationships”& earned Ph. D in Management. The research topic aimed at enhancing the contribution of manufacturing sector in GDP.

For comprehensive appreciation of multi-disciplinary issue completed the professional course from Institute of Cost & Works Accountant of India (ICWA). Life time member of Institution of Engineers & Chartered Engineer as well as approved Valuer form “Institution of Valuer”. Undertaken various training during tenure from best of institutes in India including IIM, MDI, JNIDB & RBI on different topics.

Grass root level industrial experience as Industrial Engineer in the mass production, job production & tailor made enterprises. Few of the major assignment during this tenure include ; computerization of maintenance management information system for power plant; mobilization of modernization technology development fund for gear manufacturing unit; productivity lined incentive scheme for bearing unit with National Productivity Council etc…

Extensive experience in project assessment; financing & monitoring .Few of the major assignment during this tenure include; Recovery & NPA management, introduction of Financial Services & Merchant Banking as profit centre. Extensive experience in entrepreneurship as well as cluster development; facilitation & mentoring; few of the major assignment during this tenure include; Base line surveys for some cluster in MP. Conducted Diagnostic Study & implemented BDS Market Development Project for leather cluster at Chennai; as Project Director & achieved the outcome of Log Frame. The project was of thirty month funded by multi donor International agencies including GTZ; UNDP & SIDBI. Did assignments in Bhutan; Yemen; Bahrain & Iran.

Formulated & conducted EDP & MDP in the domain of project finance; cluster development & entrepreneurship Master Trainer for some of ToT programs for entrepreneurship related initiative. Trained more than 500 executive from National & International community in the area of Project Appraisal; Banking & Enterprise Establishment Special interest in promoting & facilitating formal entrepreneurship related education in engineering & technology institute / university.

Developed & executed curriculum for subject areas of opportunity identification & assessment; project formulation having 25 credit at Entrepreneurship Development Institute of India (EDI) Presented & Published more than six papers in National & international journal of repute. Developed & reviewed manual related to Business Plan Preparation; Project Appraisal & Entrepreneur Assessment & Enterprise Service Providers for Growth etc...

International Relations

The University has collaboration with universities of International repute such as University of Saskatchewan (Canada), University of Tulsa, University of Oklahoma, University of Houston, Ontario (Canada), American Jewish Committee, Texas A & M University (USA), Georgia Tech University, University of Regina (Canada), Georgia Tech Research Corporation.

The following students from Industrial Engineering have attended International Exposure Program at Lamar University, U.S.A.:

| ROLL NO | NAME |

| 13BIE018 | KAPADIA PRAYASH DHARMESHKUMAR |

| 14BIE015 | MAKWANA DIVYANSHEE |

| 14BIE007 | PANCHAL DHRUMEET SHAILESH |

| 13BIE041 | PATEL JAY KANUBHAI |

| 13BIE043 | PATEL YASH DIVYANG |

| 13BIE044 | PATEL YASHKUMAR RAHULKUMAR |

| 13BIE051 | SANGANI SANKET CHANDUBHAI |

Industrial Relation

To develop university graduates with a basic understanding of Quality concepts to meet industry expectations a Memorandum of Understanding (MOU) was signed between Pandit Deendayal Energy University, Gandhinagar and the American Society for Quality India Pvt. Ltd (ASQ, India) to achieve three main objectives:

- Impart latest concepts of Quality through classroom workshops

- Create opportunities to work on projects relevant to industry

- Organize ASQ LMC (Local Member Community) meeting/interaction and thereby inviting industry Quality experts to share their experience.

In accordance with a mutual desire to promote a greater inter-action between industry and academia ASQ India through their Ahmedabad Local Member Community (LMC) Governing Council member has been conducting seminars/meetings and workshops for general benefit for student and faculty members. These seminars and workshops on Quality Management were conducted by the experts from Bosch Rexroth, Ford, RPG Cables, ABB etc. ASQ has also initiated a certificate scheme which will be offered to ASQ student members.

Careers in Industrial Engineering

Industrial Engineers use their problem-solving techniques in almost every organization you can imagine. Industrial Engineers may find work in in manufacturing, banks, hospitals, government organizations, transportation, construction, electronics, facility design, safety, and warehousing. Because Industrial Engineers are needed in such a large spectrum of fields, there is a variance in the type of working conditions you could expect. As an Industrial Engineer, you could be involved in such activities as: long-range planning, new facility design, installation of manufacturing systems, improvement of work flow, design of a management information system, statistical analysis, optimization studies, economic decision-making, job hazard analysis, project management, manufacturing processes improvement, inventory control, or quality control.

Consider the following sample job descriptions:

- As an industrial engineer for an airline, you might use computer simulation to decide on the best way for passengers to board airplanes

- As an ergonomist at a manufacturer of tractors, to reduce the risk of repetitive stress injuries, you may assess and change the tools that workers use or help redesign the tractor to safer and easier to use by the farmer

- As a quality manager for an automobile manufacturer, you may be responsible for supervising supplier quality by using acceptance sampling plans to monitor incoming shipments of materials

- At a manufacturer of processed food items, you may be in charge of inventory management, quality control, budgeting, and employee development, or may work to improve the product packaging to minimize product spoilage on its journey to the store

- As a quality engineer for a power company, you may improve customer satisfaction by designing a process to schedule service calls around the availability of the customer

- As an inventory controller for a greeting card company, you may be responsible for forecasting sales of cards and using those results to monitor card inventory levels and schedule card production

- As an industrial engineer in a manufacturing company, you may carry out time studies to help establish wage rates and incentive plans

- At a logistics company, you may use mathematical methods and computer models to help plan delivery routes

Industrial Engineers can work in almost all types of industries. Self-employment opportunities are also available as consultants or specialists in methods and work operation usually after suitable years of industrial experience. They can also join private consultancy firms, R & D establishments of big companies or as purchase engineers and technical sales managers. Because of the broad-based nature of the course, industrial engineers can work with all types of engineering, manufacturing and service industries in the private and public sectors.

Contact Us

Department of Industrial Engineering

School of Technology

Pandit Deendayal Energy University

Raisan, Gandhinagar-392007

Phone No.: (+91-79) 23275406.

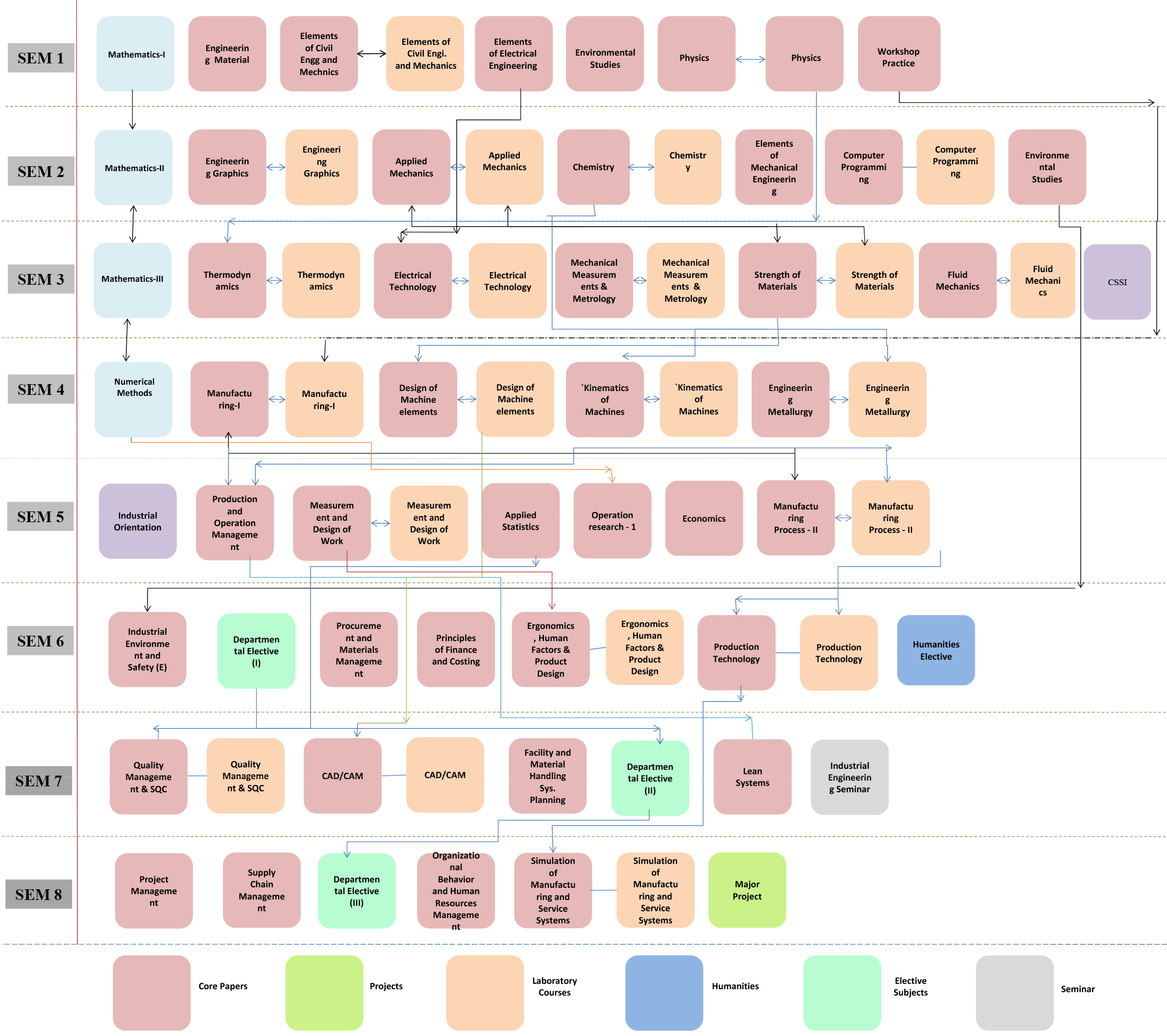

Course Curriculum

First 2 years common with mechanical engineering courses

Laboratory

Work Study(Wdm) And +Statistical Quality Vontrol(Sqc) Laboratories

Laboratory Details »

| Industrial Engineering-Laboratory Equipments | ||||

|---|---|---|---|---|

| Serial number | Semester | Name of the laboratory | Load(hours / week) | Semester |

| 1 | ODD | Quality control(QSC) | 4 | 7 |

| 2 | ODD | CAD-CAM | 8 | 7 |

| 3 | ODD | MDW LAB | 4 | 5 |

| 4 | ODD | MP-II LAB | 4 | 5 |

| 5 | ODD | MMM LAB | 4 | 3 |

| 6 | ODD | FM LAB | 4 | 3 |

| 7 | ODD | WORKSHOP | 4 | 3 |

| 8 | ODD | EMEC LAB | 4 | 3 |

| 9 | ODD | PHYSICS LAB | 4 | 1 |

| 10 | ODD | WORKSHOP | 4 | 1 |

| 11 | ODD | Communication lab | 2 | 1 |

| 12 | EVEN | Simulation of manufacturing and service system lab | 4 | 8 |

| 13 | EVEN | Ergonomics lab | 4 | 6 |

| 14 | EVEN | Production technology lab | 4 | 6 |

| 15 | EVEN | Manufacturing process -I lab | 4 | 4 |

| 16 | EVEN | DME lab | 8 | 4 |

| 17 | EVEN | KOM lab | 4 | 4 |

| 18 | EVEN | Metallurgy lab | 4 | 4 |

| 19 | EVEN | Fluid machinery lab | 4 | 4 |

| 20 | EVEN | Engineering Graphics lab | 4 | 2 |

| 21 | EVEN | Applied Mechanics lab | 4 | 2 |

| 22 | EVEN | Chemistry lab | 4 | 2 |

Seminars / Projects

Dr. Aneesh Chinubhai gave an expert talk on the topic of TQM in Manufacturing and Services as part of faculty development program in December, 2014

Supply Chain Risk Management TQM In Service Sector Bus Network Design Using OR Techniques Lean In Healthcare Industries Barriers Of Supply Chain Management Implementation In Mfg. Co. Quality Function Deployment Poka Yoke Layout Of Retail Facilities Quality Management In The Autmotive Industry Management In Hospitals Taguchi Method - Compare With Traditional DOE SMED Enterprise Resource Planning Demand Forecasting Of Petrochemical Industries Smart and sustainable packaging Applying Probabilistic Approach In Prod. Planning & Control Transport Integration Tools For SCM Third Party Logistics Lean Six Sigma Application Of TPM & KAIZEN Industrial Planning Application Of DOE In Welding Process Ergonomic design of Industrial Equipment Facility Layout Design Analysis Of FMS Using Petri-Nets ERP Techniques Use For Advanced Planning & Scheduling |

Optimization and Simulation in Railway Operation Planning Airline Crew Scheduling Importance of ERP in Organizations. Incentive Schemes In Manufacturing TPM (Total Productive Maintenance) Statistical Analysis of Prod. Process Of PTFE Products Quality Management In Conventional Energy Manufacturing DOE Application In Industry Optimization And Scheduling In Service System Materials Optimization In Boeing Facility Location Planning And Techniques Quality Control In Food Industry Optimizing Assembly Sequences Optimization Via Automation In Industries Revenue Management Plant Layout Optimization Inventory Management Of Hazardous Materials Logistics Management Statistical Quality Control In Pharmaceutical Company Demand Forecasting Reinforcement Learning In AI Role of Shipping Industry in SCM Optimization in Cutting Stock Problems |

Details of seminars/Lectures/Events conducted:

| Theme | Name, designation, and affiliation of Speaker/s participated | Date | Photographs of speakers and event |

| Guest lecture "Lean Transformation & Business" | Mr. Sujal Shah Plant leader Ingersoll Rand(INDIA), Mr. Dinesh Menon HR | 20/01/2017 |  |

| Workshop Matrox Imaging Library (MIL) Workshop: Workshop consisted of two technical session followed by hands on session on fundamental modules and different applications of image processing | Mr. E. Sureshkumar Benchmark Electronic System | 21/01/2017 |  |

Student Publications

| Sr No. | Name of conference | Date | Venue | Roll no. | Authors | Title of Paper |

| 1 | 4th Business and Management Conference | 12/10/2016 to 15/10/2016 | Istanbul, Turkey | 13BIE004 & 13BIE007 | Hunny Bhagchandani & Dilan Brahmkshatriya | Optimization of operations in inbound logistics to reduce Vehicle Transit time: A case study of India’s largest edible oil Company |

| 2 | 4th Business and Management Conference | 12/10/2016 to 15/10/2016 | Istanbul, Turkey | 13BIE007 & 13BIE004 | Dilan Brahmkshatriya & Hunny Bhagchandani | Designing on-Production line QC model: A case study of India’s largest edible oil Company |

| 3 | Startup Istanbul | 06/10/2016 to 10/10/2016 | Istanbul, Turkey | 13BIE004 & 13BIE007 | Hunny Bhagchandani & Dilan Brahmkshatriya | Torchit Electronics PVT LMT |

Research Focus

Department of Industrial engineering conducts research in the field of Quality Management in manufacturing and service systems, Measurement of Efficiency, Data Envelopment Analysis (DEA), Surface Metrology, Image Processing Techniques, Digital Signal Processing, Friction Stir Processing, Electrochemical Processing, Robotic Trajectories Optimization, Enterprise Resource Planning (ERP), Multi Criteria Decision Analysis.

In the year 2014-15 a grant worth USD 1,94,600/- in the form of software licenses was received from Simio, LLC of USA to support teaching and research activities in the area of simulation of manufacturing and service systems.

Research is an integral and important part of any higher education system. Industrial department actively promotes research among its staff and students. In addition to basic research, which is the backbone of any applied research, the institute also gives adequate importance and support to applied research. Students undertake research projects as a component of their education programme itself. Teachers conduct research as an integral part of their responsibilities since this enables them to assimilate and disseminate the knowledge as well as generate new knowledge. The students are encouraged to publish their findings in reputed journals and present papers at conferences. Department of Industrial engineering aims at developing world class research in the field of Manufacturing management, Operations research, Simulation, Supply chain management and Optimization.

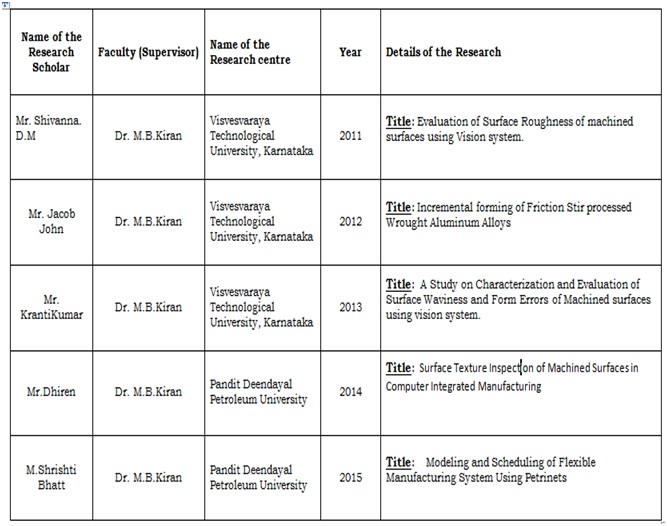

Research guidance – Ph.DDr. M. B. Kiran :

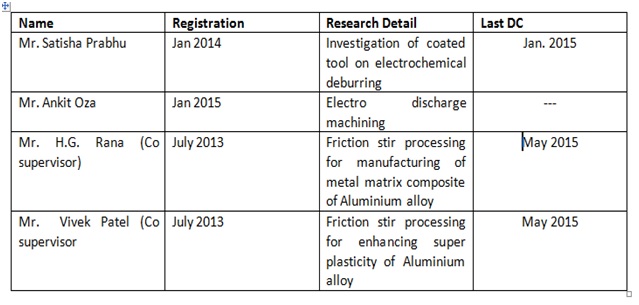

Dr. Abhishek Kumar :

Research Projects

| Area of Research | Name of the faculty member(s) | Title of Research Project/Status | Funding Agency | Amount Rs. (in lacs) |

| Industrial Engineering | Dr.M.B.Kiran | In Process Evaluation of Surface Roughness of Components in Computer Integrated Manufacturing (Completed) | All India Council For Technical Education (AICTE) | Rs. 12.5 lacs |

| Industrial Engineering | Dr. Abhishek Kumar | Optimization of Electrical Discharge Machining (EDM) Drilling Parameters Using Neural Genetic Approach For Techno-Commerical Evaluation | ORSP, PDEU, Gandhinagar | Rs. 0.7 lacs |

| Industrial Engineering | Dr. Poonam Savsani | Solving vehicle routing problem via advanced optimization algorithms | Thompson Rivers University, Kamloops , BC, Canada | $5000 Canadian Dollars |

| Industrial Inspection | Dr.M.B.Kiran | Evaluation of Flatness of Machined Surfaces Using Vision System | ORSP, PDEU, Gandhinagar | Rs. 0.5 lacs |

| Industrial Quality Control | Dr.M.B.Kiran | Evaluation of Flatness of Machined Surfaces Using Vision System | ORSP, PDEU, Gandhinagar | Rs. 0.5 lacs |

| Optimization | Dr. Poonam Savsani | Solving travelling salesman problem using metaheuristic methods | TRU, Canada | Rs. 2.5 lacs |

| Manufacturing Engineering | Mr. Kishan Ashok Fuse | Multi repsonse optimization of Glass Fiber-Reinforced Polymer (GFRP) composites using grey relational analysis | ORSP | Rs. 20000 |

Interdisciplinary Research

Department of Industrial engineering is carrying out interdisciplinary research with department of Mechanical Engineering in the field of Manufacturing, Surface Metrology, Image Processing Techniques and Optimization.

Faculty

ROLE OF FACULTY ADVISOR

On joining the School, every student is assigned to a Faculty Advisor. Students are expected to consult the Faculty Advisor on matters relating to their academic performance and the courses they may take in various semesters. The role of Faculty Advisor is to extend guidance to students, enabling them to complete their courses of study in a smooth and satisfactory manner.

Specific role of Faculty Adviser includes:- Guidance about the rules and regulations governing the courses of study.

- Registration of students for courses, within the scope of the regulations.

- Special attention to weak students, including making revised plan of study for weak/bright students based on their academic performance.

- Providing moral support to students in academic, emotional, and social/adjustment issues.

- Organizing Open House for parents or legal guardians to discuss the progress, grievances or issues of students.

- Monitoring the attendance of students from time to time in respective classes. Informing respective faculties and Director SOT about students with poor attendance.

- Monitor and review academic progress of students on regular basis.

- Encourage the students to participate in workshops, conferences, seminars, expert lectures, and participating in paper/poster presentations.

- Suggest books, journals, articles, websites, videos, or other resources to students.

- Suggest certification courses to students for overall development. Encourage students to take up projects and research studies.

- Encourage students to appear in competitive exams.

- Filing necessary paperwork on students and facilitate meetings with other faculty members.

- Sharing the progress and problems of respective students with concerned faculty members to make them aware of students needs.

- Help students maintain a balance between academic and co-curricular aspects of student life.

- Discussion about student progress with Director SOT as and when required.

Staff

Mr. Arvind Makwana

Laboratory Assistant

Students

B.TECH INDUSTRIAL ENGINEERING 2016 BATCH

| Sr. No. | Roll No. | Name of the Students |

| 1 | 16BIE001 | Abhiram Utkarsh Srivstava |

| 2 | 16BIE002 | Aditi Maheshwari |

| 3 | 16BIE003 | Aditya Sanjay Dave |

| 4 | 16BIE004 | Apoorv Agarwal |

| 5 | 16BIE005 | Arjun Patel |

| 6 | 16BIE006 | Ayush N Panchal |

| 7 | 16BIE007 | Baldha Miraj Jamanbhai |

| 8 | 16BIE009 | Bombaywala Mohammad Jahangir |

| 9 | 16BIE010 | Dalsaniya Arrown Upanjas |

| 10 | 16BIE011 | Dhananjay Chaudhary |

| 11 | 16BIE012 | Garvit Chaudhary |

| 12 | 16BIE013 | Harsh Patel |

| 13 | 16BIE015 | Jain Preet Jeevan |

| 14 | 16BIE017 | Jha Shubhamkumar Sanjaykumar |

| 15 | 16BIE018 | Karan Shah |

| 16 | 16BIE019 | Khanak Naresh Ichhuda |

| 17 | 16BIE021 | Maitra Vinod Monpara |

| 18 | 16BIE021 | Makawana Hrutvik Dashrathbhai |

| 19 | 16BIE022 | Manan Hadvani |

| 20 | 16BIE023 | Mehta Soham Abhay |

| 21 | 16BIE024 | Mendapara Nayan Prafulbhai |

| 22 | 16BIE025 | Modi Dhananj Rakesh |

| 23 | 16BIE026 | Modi Jankit Hiteshbhai |

| 24 | 16BIE027 | Mohata Yugalkishore Ramesh |

| 25 | 16BIE028 | Parshwa Bhansali |

| 26 | 16BIE029 | Patel Arpan Harshad |

| 27 | 16BIE030 | Patel Deep Narendrakumar |

| 28 | 16BIE032 | Patel Kishan Ganpatbhai |

| 29 | 16BIE033 | Patel Ritu Rajendrabhai |

| 30 | 16BIE034 | Patel Vedant Nileshbhai |

| 31 | 16BIE035 | Prabhakar Prashant Hitendrakumar |

| Sr. No. | Roll No. | Name of the Students |

| 32 | 16BIE036 | Prajapati Sunny Rajubhai |

| 33 | 16BIE037 | Purva Shah |

| 34 | 16BIE038 | Rajput Anuragsingh Rambaransingh |

| 35 | 16BIE039 | Rishabh Pritesh Shah |

| 36 | 16BIE040 | Salonee Jain |

| 37 | 16BIE041 | Sankshit Pandoh |

| 38 | 16BIE042 | Shah Armaan |

| 39 | 16BIE043 | Shah Ishan Jignesh |

| 40 | 16BIE045 | Solanki Vaibhav Harish |

| 41 | 16BIE047 | Vyas Bhargav Jatin |

| 42 | 16BIE049 | Yadav Shubhamkumar Sudershankkumar |

| 43 | 16BIE050 | Bhojani Deep Kantibhai |

| 44 | 16BIE051 | Chikhaliya Deepkumar Sureshbhai |

| 45 | 16BIE053 | Dhananjay Kushwah |

| 46 | 16BIE054 | Faldu Priyank Girdharbhai |

| 47 | 16BIE055 | Ganatra Dhvanit Kishorbhai |

| 48 | 16BIE056 | Harsh Pruthvisingh Sisodiya |

| 49 | 16BIE057 | Kabra Vedant |

| 50 | 16BIE058 | Khant Manthankumar Bhagvanbhai |

| 51 | 16BIE059 | M Viraal |

| 52 | 16BIE060 | Nayak Dhruvil Viralkumar |

| 53 | 16BIE061 | Nitish Sharma |

| 54 | 16BIE062 | Patel Sanket Pravinbhai |

| 55 | 16BIE063 | Preetkumar Kalavadia |

| 56 | 16BIE064 | Sheilja Bhatt |

| 57 | 16BIE065 | Tiwari Ashutosh Ramashankar |

| 58 | 16BIE066 | Zala Karanrajsinh Dharmarajsinh |

| 59 | 16BIE067 | Soni Rohan Sanjay |

| 60 | 16BIE068 | Yash Patel |

| 61 | 15BIE001 | Acharya Priyesh Kanaiyalal |

| 62 | 15BIE035 | Nair Amiraj M |

B.TECH INDUSTRIAL ENGINEERING 2015 BATCH

| Sr. No. | Roll No. | Name of the Students |

| 1 | 15BIE002 | Kush Adhvaryu |

| 2 | 15BIE003 | Ashish Agrawal |

| 3 | 15BIE004 | Bhaumik Ashar |

| 4 | 15BIE005 | Jay Bhandari |

| 5 | 15BIE006 | Anand Bhesdadiya |

| 6 | 15BIE007 | Rushik Borad |

| 7 | 15BIE008 | Chaudhari Chintan Jashubhai |

| 8 | 15BIE009 | Yash Dhingani |

| 9 | 15BIE010 | Devvrat Doshi |

| 10 | 15BIE011 | Pranjal Dubal |

| 11 | 15BIE012 | Khushboo Gangvekar |

| 12 | 15BIE013 | Gaud Aakash Chetnarayan |

| 13 | 15BIE014 | Ghadiyali Chittvan |

| 14 | 15BIE015 | Kaushal Gohel |

| 15 | 15BIE016 | Vishal Gohel |

| 16 | 15BIE017 | Manan Hingorani |

| 17 | 15BIE018 | Darshitkumar Jagetiya |

| 18 | 15BIE019 | Vaibhav Jain |

| 19 | 15BIE020 | Santosh Jethwani |

| 20 | 15BIE021 | Jivani Rushikumar Vijaybhai |

| 21 | 15BIE022 | Akshata Joshi |

| 22 | 15BIE024 | Jay Kamani |

| 23 | 15BIE025 | Enil Kansagra |

| 24 | 15BIE026 | Parshwa Vikram Kapadia |

| 25 | 15BIE027 | Shreshth Khurana |

| 26 | 15BIE028 | Raj Koradia |

| 27 | 15BIE029 | Umang Maru |

| 28 | 15BIE030 | Mehta Navil Dhirajkumar |

| 29 | 15BIE031 | Parth Modhia |

| 30 | 15BIE032 | Manmit Mody |

| 31 | 15BIE033 | Jatin Motwani |

| 32 | 15BIE034 | Sneh Mulani |

| 33 | 15BIE036 | Parth Pant |

| 34 | 15BIE037 | Rucha Parikh |

| 35 | 15BIE038 | Patel Aakashkumar Dineshbhai |

| 36 | 15BIE039 | Darshankumar Patel |

| 37 | 15BIE040 | Patel Parth Vipulbhai |

| 38 | 15BIE041 | Parth Patel |

| 39 | 15BIE042 | Patel Shival |

| Sr. No. | Roll No. | Name of the Students |

| 40 | 15BIE043 | Patel Vedang Shaileshkumar |

| 41 | 15BIE044 | Vyom Patel |

| 42 | 15BIE045 | Prajapati Trushali |

| 43 | 15BIE046 | Raj Raiyani |

| 44 | 15BIE049 | Raol Yashrajsingh H |

| 45 | 15BIE050 | Satodiya Denish |

| 46 | 15BIE051 | Aditya Shah |

| 47 | 15BIE052 | Mauli Shah |

| 48 | 15BIE053 | Shah Parth |

| 49 | 15BIE054 | Aditi Sharma |

| 50 | 15BIE055 | Ujas Shukla |

| 51 | 15BIE056 | Abhishek Singh |

| 52 | 15BIE057 | Ashray Unadkat |

| 53 | 15BIE058 | Monal Vaishnani |

| 54 | 15BIE059 | Piyush Verma |

| 55 | 15BIE060 | Rajvee |

| 56 | 14BIE005 | Rajat Chaudhary |

| 57 | 14BIE020 | Panchal Shreya Maheshkumar |

| 58 | 14BIE053 | Patel Neel Dharmeshkumar |

| 59 | 14BIE056 | Patel Yash S. |

| 60 | 14BIE061D | Katariya Deepakkumar Chhaganbhai |

| 61 | 15BIE061D | Bhimani Parthkumar Rameshbhai |

| 62 | 15BIE062D | Chauhan Niranjan Sumanchandra |

| 63 | 15BIE063D | Chavada Kuldeep Rameshbhai |

| 64 | 15BIE064D | Gopani Vairagbhai Himatlal |

| 65 | 15BIE065D | Hirani Vivek RajubhaiHirani Vivek Rajubhai |

| 66 | 15BIE066D | Patel Akash Babubhai |

| 67 | 15BIE067D | Shah Purvish Rashmikant |

| 68 | 15BIE068D | Shukla Raj Hiten |

| 69 | 15BIE069D | Sodha Keyur Bhupendrakumar |

| 70 | 15BIE070D | Trivedi Akash Chandresh |

| 71 | 15BIE071D | Vaghasia Vatsal Maheshkumar |

| 72 | 15BIE072D | Dhaneja Jigar Prafulbhai |

| 73 | 15BIE073D | Harshul P Patel |

B.TECH INDUSTRIAL ENGINEERING 2014 BATCH

| Sr. No. | Roll No. | Name of the Students |

| 1 | 14BIE002 | Belagali Nikhil Mukund |

| 2 | 14BIE003 | Bhansali Surbhi Rajendra |

| 3 | 14BIE004 | Chaudhari Jay Dineshbhai |

| 4 | 14BIE006 | Dave Prathit |

| 5 | 14BIE007 | Dhrumeet Shailesh Panchal |

| 6 | 14BIE008 | Drashti |

| 7 | 14BIE009 | Jain Ujjwal Niraj |

| 8 | 14BIE010 | Jasani Nihar |

| 9 | 14BIE012 | Kathrecha Kirtan Nikhil |

| 10 | 14BIE013 | Kumar Vipul Dileep |

| 11 | 14BIE014 | Lakhani Yash Raju |

| 12 | 14BIE015 | Makwana Divyanshee Rajesh |

| 13 | 14BIE016 | Malani Mohil Vinodbhai |

| 14 | 14BIE017 | Mevada Manan Maheshkumar |

| 15 | 14BIE018 | Mohammed Irfan |

| 16 | 14BIE021 | Panchal Tanak Manan |

| 17 | 14BIE022 | Parikh Maulik |

| 18 | 14BIE025 | Patel Dipen Pankajkumar |

| 19 | 14BIE026 | Patel Ishan Deepakkumar |

| 20 | 14BIE027 | Patel Nikunjkumar Mansukhbhai |

| 21 | 14BIE028 | Patel Smit Bharatbhai |

| 22 | 14BIE029 | Patel Utkarsh R |

| 23 | 14BIE030 | Patel Yash Babubhai |

| 24 | 14BIE031 | Prajapati Hardik |

| 25 | 14BIE032 | Satasiya Gunjan Ramjibhai |

| 26 | 14BIE034 | Shah Jay Sanjaybhai |

| 27 | 14BIE035 | Shaikh Imranali Sharafatali |

| 28 | 14BIE036 | Thakkar Parth Haribhai |

| 29 | 14BIE037 | Thakur Rajendra |

| Sr. No. | Roll No. | Name of the Students |

| 30 | 14BIE038 | Tiwari Ronak Ramvishal |

| 31 | 14BIE039 | Tiwari Shashank Shashikant |

| 32 | 14BIE040 | Trivedi Sharvin Rajeshkumar |

| 33 | 14BIE041 | Vaishnav Aditya Dineshbhai |

| 34 | 14BIE042 | Vishruth Ashok Kumar |

| 35 | 14BIE043 | Vora Faiz F |

| 36 | 14BIE044 | Walia Ishita |

| 37 | 14BIE045 | Yadav Mihir J |

| 38 | 14BIE046 | Zinzala Punit Nagjibhai |

| 39 | 14BIE047 | Zinzuwadia Vidit Vipul |

| 40 | 14BIE048 | Bajaj Rushiraj |

| 41 | 14BIE050 | Jaspuriya Grishma Himanshu |

| 42 | 14BIE051 | Kakustam Hari Chandana |

| 43 | 14BIE052 | Pandit Yug |

| 44 | 14BIE055 | Singh V. Yuvraj V.P.Singh |

| 45 | 14BIE058D | Gajera Rushit J |

| 46 | 14BIE059D | Jadeja Jayrajsinh M |

| 47 | 14BIE060D | Joshi Dhaval R |

| 48 | 14BIE062D | Malaiya Hiteshkumar H |

| 49 | 14BIE063D | Patel Harshkumar G |

| 50 | 14BIE065D | Solanki Jay R |

| 51 | 14BIE066D | Thanki Savan H |

| 52 | 14BIE068D | Dhruval V. Panchal |

| 53 | 14BIE069D | Nand Patel |

| 54 | 14BIE070D | Shiyani Siddharth Rajeshbhai |

| 55 | 13BIE003 | Pranav Barad |

B.TECH INDUSTRIAL ENGINEERING 2013 BATCH

| Sr. No. | Roll No. | Name of the Students |

| 1 | 12BIE007 | Dixitkumar Chaudhary |

| 2 | 12BIE018 | Vishwaraj Manhar Jariwala |

| 3 | 12BIE024 | Jayant Malaviya |

| 4 | 13BIE001 | Agarawal Shivam Ghanshyam Das |

| 5 | 13BIE002 | Aghera Jaymin Mahendra |

| 6 | 13BIE004 | Bhagchandani Hunny Jagdishkumar |

| 7 | 13BIE005 | Bhatt Dhruv Narendra |

| 8 | 13BIE006 | Bhatt Nihal Deepak |

| 9 | 13BIE007 | Brahmkshatriya Dilan |

| 10 | 13BIE008 | Chaudhari Priyank Kumar Vipulbhai |

| 11 | 13BIE010 | Dave Divij Nimeshbhai |

| 12 | 13BIE011 | Dholariya Ankit Rameshbhai |

| 13 | 13BIE012 | Fathwani Aadesh Kumar Kamal Kumar I |

| 14 | 13BIE013 | Gandhi Paritosh Jagdishbhai |

| 15 | 13BIE014 | Gandhi Yash Deepakbhai |

| 16 | 13BIE015 | Jaiswal Yash Mahesh |

| 17 | 13BIE017 | Joshi Ritesh Nikhilbhai |

| 18 | 13BIE018 | Kapadia Prayash |

| 19 | 13BIE019 | Khatri Jatin Manoj |

| 20 | 13BIE021 | Kotak Rohan Ghanshyambhai |

| 21 | 13BIE022 | Lalwala Soham Rajendra |

| 22 | 13BIE023 | Limbachiya Parth Maheshbhai |

| 23 | 13BIE025 | Malani Chirag |

| 24 | 13BIE028 | Mistry Meet Sunilbhai |

| 25 | 13BIE029 | Modi Jay Satishkumar |

| 26 | 13BIE030 | Nasit Ravi Girishbhai |

| 27 | 13BIE033 | Pandya Yash Vinodchandra |

| Sr. No. | Roll No. | Name of the Students |

| 28 | 13BIE034 | Parmar Bhargav Narottambhai |

| 29 | 13BIE035 | Parmar Vyom Dharmendrasinh |

| 30 | 13BIE036 | Patel Ankitkumar Shaileshbhai |

| 31 | 13BIE038 | Patel Harsh Mukeshbhai |

| 32 | 13BIE039 | Patel Harsh Sureshbhai |

| 33 | 13BIE040 | Patel Jay Atulkumar |

| 34 | 13BIE041 | Patel Jay Kanubhai |

| 35 | 13BIE042 | Patel Jaykishan Nitin Patel |

| 36 | 13BIE043 | Patel Yash |

| 37 | 13BIE044 | Patel Yashkumar Rahulbhai |

| 38 | 13BIE045 | Yaman Kalyan Pattanaik |

| 39 | 13BIE046 | Prajapati Dhruv MukeshkumarPrajapati Parth |

| 40 | 13BIE047 | Prajapati Parth |

| 41 | 13BIE048 | Prajapati Shraddhaben Ramanlal |

| 42 | 13BIE049 | Rajkotiya Harsh Hareshbahi |

| 43 | 13BIE050 | Rawat Keshav |

| 44 | 13BIE051 | Sangani Sanket Chandubhai |

| 45 | 13BIE052 | Shah Dhruvin Manish |

| 46 | 13BIE053 | Shah Kartik Dhaneshbhai |

| 47 | 13BIE054 | Sheth Nishit Vyomeshkumar |

| 48 | 13BIE055 | Ronita Singh |

| 49 | 13BIE056 | Varsha Singh |

| 50 | 13BIE058 | Soni Rajan Jagdishbhai |

| 51 | 13BIE059 | Sawan Sunil Suba |

| 52 | 13BIE060 | Trivedi Shivam Sanjaykumar |

| 53 | 13BIE061 | Vikas Yadav |

| 54 | 13BIE062 | Zinzala Gopal Jethabhai |

Alumni

|

Karan Desai Khs Machinery Pvt ltd Supply Chain |

|

Karan Thakkar Patels Airflow Pvt. Ltd. TQM, Lean Manufacturing, Project Management, Procurement and Materials Management, etc. |

|

Mehul Parekh Weir Minerals India Pvt. Ltd., Bangalore Quality Management,Lean Systems, Operational Research, Facality layout planning |

|

Himani Mehta Kalptaru Power Transmission Pvt. Ltd., Gandhinagar Lean systems |

|

Raj Patel Zydus hospira oncology pvt. ltd,mateda,Bavla Lean manufacturing, facility planning and material handling,stastical quality control |

|

Tanmay Porwal Mondelēz International, Thane (Mumbai) Production and Operation Management |

|

Devik Sodha Landmark Honda Project Management, Operations Management, Logistics, Quality Control |

|

Kapilkumar Kyada Patels Airflow Pvt. Ltd. finance and costing |

|

Sameep Khatri ONGC, HAZIRA Operational Management, Statistical Quality Control, Design Of Experiments, Psychology |

|

Samved Vora Heena Engineering, Vatva Operations Research |

|

Urvish Solanki Essar steel India limited - surat TPM,Statistical quality control

|

|

Krishna Desai L&T ltd,hazira Surat. Operational Research |

|

Manu Arya HINDUSTAN ZINC, VEBARI, UDAIPUR Operations Management, Organizational Behavior |

|

Mohil Radia WaterForce Pumps Ahmedabad Operations Research

|

|

Nikhil Dwivwdi L&T Vadodara Switchgear Works CAD/CAM |

|

Prakrut Dalwadi ESSAR STEEL INDIA LTD, Hazira Facility Supply Chain Management |

|

Darshan Karia Elecon Engineering company ltd. Principles of finance and costing. |

|

Deep Dave Hindustan Coca-Cola Beverages Pvt. Ltd.,Goblej,Kheda,Gujarat Lean System |

|

Nisarg Shah Ferromatik Milacron, Vatva, Ahmedabad Supply Chain Management |

|

Yash Thakar Patel Airflow Pvt. Ltd., Vatva, Ahmedabad Engineering Graphics

|

|

Dhruv Patel chem process system pvt. ltd, sanand production technology, |

|

Rajat Patel Cadilla Healthcare , Ankleshwar Project Developing |

|

Rahil Patel logistics in fleet transportation Logistics |

|

Yagnik Savaliya cadila healthcare Work System Design |

|

Vaibhav Chajeer Colgate Palmolive Sanand, Gujarat. Statistical Quality Control |

|

Vishal Derashri Khs Machinary Pvt ltd Quality Management |

|

Rushabh Doshi Hindustan CocaCola Beverages Pvt. Ltd., Goblej Production and operations management |

|

Nishika Agarwal CTM Technical Textile, Kadi; KPMG Gandhinagar Operations Research, quality management, production and operations management |

|

Hardik Mehta Windsor machines ltd. (Chattral) Operations Research. |

|

Parth kumar Devani Elecon Engineering Engineering Drawing |

|

Harsh Patel Hindustan coca cola beverages private limited Lean manufacturing, facility planning and material handling, statistical quality control |

|

Gaurang Manek Elecon Engineering principles of finance and costing |

|

Rushikesh Patel reliance lpg Private limited,sanand Quality statistical control |

|

Jaykumar Nanwani Elecon Engg. Principles Of Operation Management

|

|

Kishan Vora Anupam-MHI Industries Ltd Operation research |

|

Surabhi Agarwal Aum Electrical Industries, Vadodara Lean Management |

|

RutvikRaj Raol WINDSOR MACHINES PVT. LTD., CHATTRAL production of managment |

|

Mehul Patel Anupam-MHI Industries Ltd., Nadiad Principles of finance and costing |

|

Dhanraj Raval Peass Industrial Engineers Pvt Ltd Navsari Work Design and Measurement,

|

|

Nirja Shah Mundra Adani Port, Gujarat Supply Chain Management |

|

Nupur Parekh Add Value Consultancy Inc.- Safal Solitaire,beside Porsche showroom, S.G. highway,Ahmedabad. Production and operations management, Lean systems, probability and statistics. |

|

Shivani Pandya Arvind Ltd. , Santej, Ahmedabad statistical quality management, operation manegment,supply chain management, ergonomics, Facility Layout |

|

Amruta Shukla Larsen & toubro Hazira Optimisation |

|

Darshan Neshadiya Suntouch laminate Pvt.Ltd. at Morbi Operational research |

|

Malav Bhatt Windsor machines limited Production Technology,manufacturing process |

|

Deepti Poduval ADD VALUE consultancy Project management |

|

Rahul Tundel Hindustan CocaCola Beverages Pvt. Ltd., Goblej Project management |

|

Niraj Kumar Diesel Locomotive Works, Varanasi Operations Research, Manufacturing Process, Supply Chain Management, Computer Programming(C,C++,JAVA) |

|

Shubhra Singh ONGC , AHMEDABAD(AVANI BHAVAN) Material Management, Lean Manufacturing, Facility Layout, Supply Chain Management, Operation Management, Quality Control. |

Chapters And Society Activities

Tark

Tark is a student club of the department of Industrial Engineering. The club organizes activities like expert lectures, seminars and workshops related to Industrial Engineering.

American Society for Quality (ASQ) – Student Chapter

With the growing importance of Quality Management in industry in today’s world, the department has taken an initiative to start a student chapter of the American Society for Quality (ASQ) at PDEU. The student chapter invites speakers from industry and organizes workshops and seminars related to Quality Management. A certification scheme has also been implemented by ASQ for PDEU students wherein students completing a series of workshops will be awarded a certificate by the American Society for Quality. ASQ, formerly known as the American Society for Quality and the American Society for Quality Control (ASQC), is knowledge- based global community of quality professionals, with nearly 80,000 members dedicated to the promotion and advancement of quality tools, principles, and practices in their workplaces and in their communities.

Seminar on Lean Manufacturing for Productivity Enhancement

Students of Industrial Engineering attended a seminar on Lean Manufacturing for Productivity Enhancement organized by the National Productivity Council (NPC). Twenty-four students from IE participated in the seminar.

Two days workshop entitled “Autonomous Robots using Microcontroller- AVR” organized jointly with the Mechanical Engineering department.

Students of Industrial Engineering were part of a team representing PDEU at BAJA 2013 organized by the Society of Automotive Engineers

Students of Industrial Engineering participate in a technical club called MECHINERZO (Mechanical and Indsutrial Engineers’ Zone). This club carries out various technical activities related to Mechanical and Industrial Engineering.

Workshop

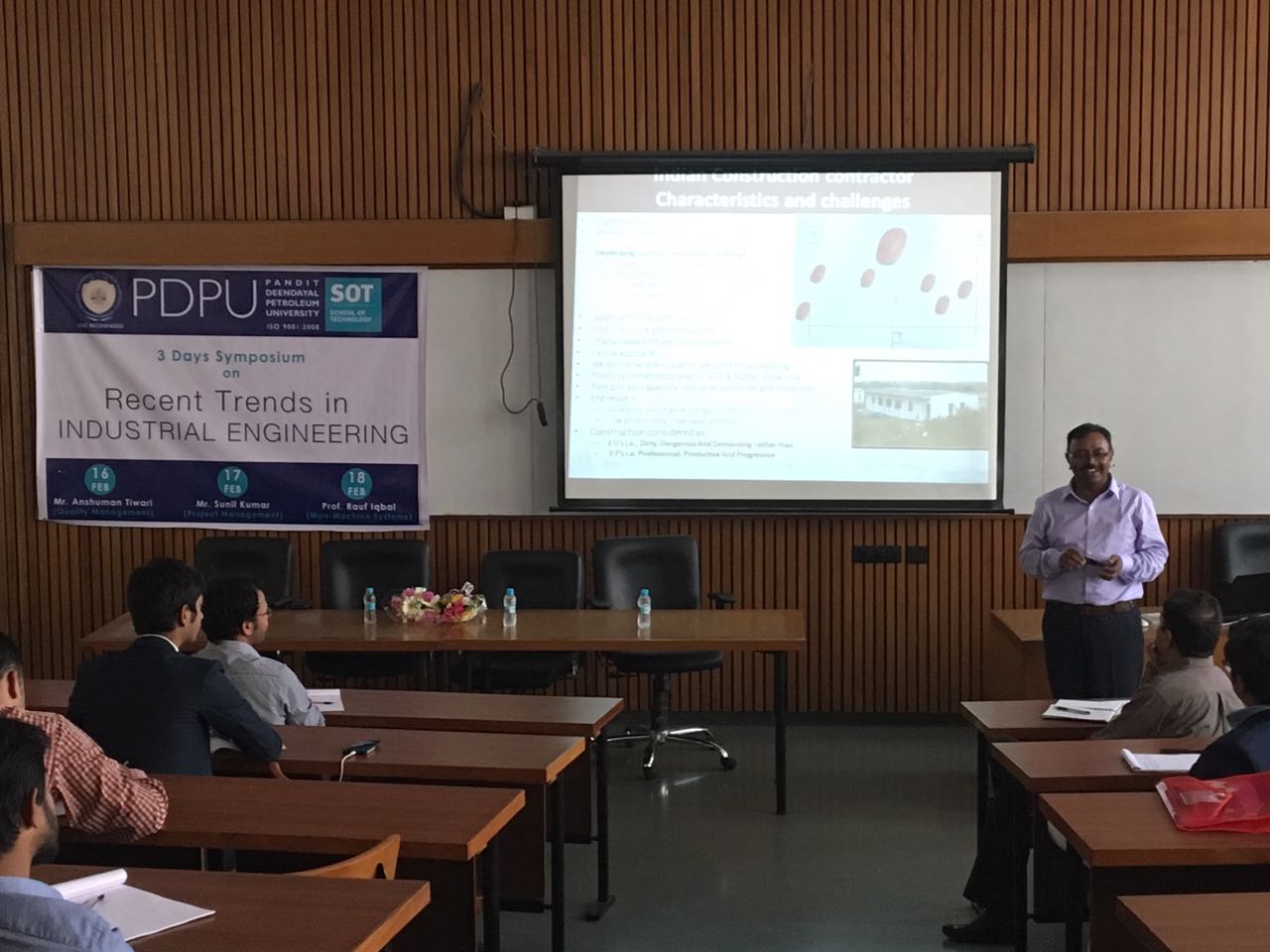

“Recent Trends in Industrial Engineering”

16th - 18th February, 2017

Industrial Engineering department has organized a three days workshop to create awareness among the students about recent tools and techniques used in industries. The mission of conducting such workshop is to spread the awareness of recent advancement in industrial engineering to the students so that they can be industry ready. This workshop will enhance their employability.

Coordinators:

- Dr. M. B. Kiran

- Mr. Manish Mishra

- Dr. Abhishek Kumar

- Dr. Poonam Savsani

For details click below link: Recents trends in IE_Workshop

Day 1:Speaker: Mr. Anshuman Tiwari

Head of Process Re-engineering (Offshore), HSBC

Speaker: Mr. Sunil Kumar

Experienced Project Professional

Speaker: Prof. Rauf Iqbal

Professor in Ergonomics and Human Factors Engineering at NITIE, Mumbai

Activity Calendar 2019-2020

| Sr. No. | Name of the Event | Date |

|---|---|---|

| 1 | Lean Six Sigma Green Belt Workshop (4 Days) | 1st, 2nd , 8th and 9th April, 2019 |

| 2 | General Body Meeting | 4th August, 2019 |

| 3 | Continual improvement techniques-II | 12th August, 2019 |

| 4 | Guest lecture | 17th August, 2019 |

| 5 | Industrial Engineering | 19th August, 2019 |

| 6 | Guest lecture | 28th August, 2019 |

| 7 | 3-day Workshop | 8-10th September, 2019 |

| 8 | Guest lecture | 11th September, 2019 |

| 9 | Lean management | 16th September, 2019 |

| 10 | Six Sigma | 23rd September, 2019 |

| 11 | Guest lecture | 25th September, 2019 |

| 12 | General management | 14th October, 2019 |

| 13 | Guest lecture | 16th October, 2019 |

| 14 | Guest lecture | 30th October, 2019 |

| 15 | Guest lecture | 6th November, 2019 |

| 16 | Workshop | 10th November, 2019 |

| 17 | Industrial Visit (4th year) | 11th November, 2019 |

| 18 | History and Basic Q-Terminology | 18th November, 2019 |

| 19 | Guest lecture | 21st November, 2019 |

| 20 | Industrial Visit (4th year) | 25th November, 2019 |

| 21 | Continual Improvement Techniques - I | 2nd December, 2019 |

| 22 | 5S understanding and Implementation | 16th December, 2019 |

| 23 | Quality Management Systems | 20th January, 2020 |

| 24 | Guest lecture | 30th January, 2020 |

| 25 | Statistical Process Control | 3rd February, 2020 |

| 26 | Industrial Visit (3rd year) | 10th February, 2020 |

| 27 | Industrial Visit (3rd year) | 17th February, 2020 |

| 28 | 3-day Workshop | 23-25th February, 2020 |

| 29 | Guest lecture | 9th March, 2020 |

| 30 | Guest lecture | 20th March, 2020 |

Campus Recruitment

| Concept Business Excellence Pvt. Ltd | GACL | Hindustan Coca-Cola Beverages Pvt. Ltd. | Infosys | Tata Chemical Ltd. |

| Companies that Visit us: | |

|---|---|

|

|

Industrial Internship

Industrial Training :A student is required to undergo 6 to 8 weeks of Industrial Training in the non-teaching period of the Third year of the B.Tech. Program as partial requirement for the award of the degree. This training can be carried out either in Industry, at an R&D organization, or Schools of Technology/Departments of Universities.

The comprehensive evaluation/examinations of every internship/ orientation are held soon after its completion.

Objectives :- To expose students to various operations of industry for enhancing their understanding about application of science and engineering principles studied in first two years of B. Tech programme.

- To develop students’ understanding about industry operations to facilitate their academic and research learning for the 3rd and 4th year B. Tech programme.

- To create broader understanding of operations of domestic engineering practices and field expectations of fresh graduates for entry level employability.

- To expose students to latest technology deployment for quality and cost-effective outputs.

- Sensitize students with socially responsible behaviour wherever they are placed in future.

- Projection of School of Technology and PDEU as a socially responsible organization.

- Enhance skills of students. i.e. observation skill, analytical skill, decision making skill, communication skill.

INDUSTRY ORIENTATION

Industry Orientation :

A student is required to undergo 3 weeks of Industry Orientation distributed along the 4th and 5th Semesters as partial requirement for the award of the degree. This would be at one or more related industry units.

The comprehensive evaluation/examinations of every internship/ orientation are held soon after its completion.

Objectives :- To expose students to various operations of industry for enhancing their understanding about application of science and engineering principles studied in first two years of B. Tech programme.

- To develop students’ understanding about industry operations to facilitate their academic and research learning for the 3rd and 4th year B. Tech programme.

- To create broader understanding of operations of domestic engineering practices and field expectations of fresh graduates for entry level employability.

- To expose students to latest technology deployment for quality and cost-effective outputs.

- Sensitize students with socially responsible behaviour wherever they are placed in future.

- Projection of School of Technology and PDEU as a socially responsible organization.

- Enhance skills of students. i.e. observation skill, analytical skill, decision making skill, communication skill.

CSSI / Rural Internship

Civic & Social Service Internship (CSSI) :

A student is required to undergo 3 weeks of Civic & Social Service Internship at the end of the second semester as partial requirement for the award of the degree.

The comprehensive evaluation/examinations of every internship are held soon after its completion.

Objectives :- To strengthen understanding on concepts of rural development with specific reference to the Indian context.

- To provide exposure to grassroots realities, in the rural setting, with a focus on participation in interventions by NGOs.

- To strengthen insights and develop skills on participatory methodologies and tools used in rural development.

- To understand and appreciate broader contexts of other stakeholders, like government agencies, donors and local self-governance institutions, while participating in existing field projects.

- To facilitate cross-cultural learning on development issues as well as other areas of inter-personal growth and learning.

- Sensitized workforce in energy sector who are socially concerned and willing to positively contribute to the society.

- Increased awareness about rural areas in students.

- Thorough understanding about the rural socio-economic scenario in students.

- Understanding the functioning of rural areas and nonprofit sector.

- Explore challenging issues in existing systems and suggest possible solutions.

- Identify opportunities in rural areas.

- Enhanced understanding among students about rural development and rural management.

R & D

| Area of Research | Name of the faculty member(s) | Title of Research Project/Status | Funding Agency | Amount Rs. (in lacs) |

| Industrial Engineering | Dr.M.B.Kiran | In Process Evaluation of Surface Roughness of Components in Computer Integrated Manufacturing (Completed) | All India Council For Technical Education (AICTE) | Rs. 12.5 lacs |

| Industrial Engineering | Dr. Abhishek Kumar | Optimization of Electrical Discharge Machining (EDM) Drilling Parameters Using Neural Genetic Approach For Techno-Commerical Evaluation | ORSP, PDEU, Gandhinagar | Rs. 0.7 lacs |

| Industrial Engineering | Dr. Poonam Savsani | Solving vehicle routing problem via advanced optimization algorithms | Thompson Rivers University, Kamloops , BC, Canada | $5000 Canadian Dollars |

| Industrial Inspection | Dr.M.B.Kiran | Evaluation of Flatness of Machined Surfaces Using Vision System | ORSP, PDEU, Gandhinagar | Rs. 0.5 lacs |

| Industrial Quality Control | Dr.M.B.Kiran | Evaluation of Flatness of Machined Surfaces Using Vision System | ORSP, PDEU, Gandhinagar | Rs. 0.5 lacs |

| Optimization | Dr. Poonam Savsani | Solving travelling salesman problem using metaheuristic methods | TRU, Canada | Rs. 2.5 lacs |

| Manufacturing Engineering | Mr. Kishan Ashok Fuse | Multi repsonse optimization of Glass Fiber-Reinforced Polymer (GFRP) composites using grey relational analysis | ORSP | Rs. 20000 |

Recent Publications

- M.B. Kiran, B. Ramamoorthy, V. Radhakrishnan., 1998. Evaluation of surface roughness by vision system. International Journal of machine Tools and Manufacture. Volume 38(5-6): pp 685- 690.

- M.B.Kiran, H.Ramakrishna and Prabhakar Kuppahalli, A Study on the Evolution of Surface Roughness Characterization, Manufacturing Technology Today, Volume 11, Issue 1-2, Jan-Feb 2012.

- Shivanna D.M and M.B.Kiran, A Comparative Study to Assess the Effectiveness of Surface Texture Classification Algorithms, International Journal of Engineering Research & Technology, ISSN: 2278-0181, Vol. 1, Issue 7, September-2012.

- Ravindra Biradar, M.B.Kiran, “The Dynamics of Fixed Base and Free-Floating Robotic Manipulator”, International Journal of Engineering Research & Technology, ISSN: 2278-0181,Vol. 1 (5), 2012, 1-9.

- M.B.Kiran et.al., Texture Feature Analysis of Milled Components Using Vision System, Advanced Materials Research, pp 745-749,2014.

- M.B.Kiran et.al., Evaluation of 3D Surface Roughness Parameters of EDM Components Using Vision System, Procedia Materials Science 5, 2132 – 2141,2014.

- M.B.Kiran et.al., 'Flexible manufacturing system modeling – Petrinet Based approach'-A Survey, International Journal of Advanced Mechanical Engineering, pp. 741-746, Number 7, 2014.

- M.B.Kiran et.al., 'Three Dimensional Surface Roughness Evaluation of Machined Components in Computer Integrated Manufacturing', International Journal of Latest Technology in Engineering, Management & Applied Science, pp187-193, Volume III, Issue VI, June 2014.

- M.B.Kiran et.al., “A Survey on Out of Roundness Measuring Methods", Accepted for publication in International Journal of Research and Scientific Innovation" (Volume I Issue II), 2014.

- M.B.Kiran et.al, In-process measurement of surface roughness of Milled components Using computer vision system, Journal of Mechanical Engineering Research and Technology, Volume 2, Number 1, pp.231-246,2014.

- Dr D M Parikh; Scaling up through outsourcing using entrepreneurial & sustainable strategy- case study of Indian corporate. SANLALPA :Journal of management &Resaerch,vol-5 conference issue(Feb-2015),ISSN No. 2231-1904 and impact factor 2.372,201-206

- D M Parikh; Business to Responsible Business a Sustainable Strategy of Survival & Growth for all, Indian Journal of Applied Research ,vol-3,issue-6 June 2013 ; IISN-2249-555X,51-54

- D M Parikh, Facilitation of collateral free loan to improve financial linkages for start -up & Growth- A case study, Global Research Analysis ,vol-1,isuue-1 June-2012 ; ISSN No- 2277-8160,44-46

- D M Parikh; Innovation & Initiative in Infrastructure Financing: A perspective ; Journal of Industrial Research ;issue April-June-2008,3-23

- D M Parikh; HRD-for Change and Innovation, Leather Research Industry Get-Together 2012.

- D M Parikh; Industrial Engineer as a BDS Provider & Facilitator an Enlarged role in the Globalised Economy ; International Conference on Industrial Engineering (ICIE-2011);48-50

- Kumar, A., Clement, S. and Agrawal, V. P. (2011) Quality Modeling and Analysis of Electroplating System Using Graph Theory Matrix Approach, International Journal of Productivity and Quality Management, 8, 85-112. (Inder Science Publication)

- Kumar, A., Clement, S. and Agrawal, V. P. (2011) Concurrent Design of Electroplating System for X- Abilities: A Graph Theoretic Approach, International Journal of Industrial and Systems Engineering, 9, 350-371 (Inder Science Publication)

- Kumar, A., Clement, S. and Agrawal, V. P. (2011) Optimum Selection and Ranking of Electroplating System Process Parameters: Taguchi-MADM Approach, International Journal of Applied Decision Science, 4, 341-361 (Inder Science publication)

- Kumar, A., Clement, S. and Agrawal, V. P. (2010) Structural modeling and analysis of an effluent treatment process for electroplating – A graph theoretic approach, Journal of Hazardous Materials, 179, 748-761. (Elsevier Publication, Impact factor: 4.144)

- Kumar, A., Clement, S. And Agrawal, V. P. (2010) Attribute Based Design Specification, Comparison and Selection of Electroplating Waste Treatment System Using MADM Approach, Journal of Tribology and Surface Engineering, 1, 263-286. (Nova Publication, USA)

- Kumar, A. and Agrawal, V. P. (2009) Attribute based specification, comparison and selection of electroplating system using MADM approach, Expert System with Application, 36, 10815- 10827. (Elsevier Publication, Impact factor: 2.908)

- Kumar, A. and Agrawal, V. P. (2008) Structural modelling and analysis of electroplating system: a graph theoretic system approach, International Journal of Surface Science and Engineering, 2, 520 – 540. (Inder Science publication)

- Poonam Savsani ,"Comparative Study of Different Metaheuristics for the Trajectory Planning of a Robotic Arm" , is published in the IEEE- Systems Journal.

- 'Comparative Study of Different Metaheuristics for the Trajectory Planning of a Robotic Arm', IEEE system journal, pp. 1-12, Jul 2014.

- 'Optimal Motion Planning For a Robot Arm by Using Artificial Bee Colony (ABC) Algorithm', Journal of Modern Engineering Research, pp. 44434-4438, May 2012.

- Mr. V. Balaji Rao, Interpretive Structural Modeling Technique for Hierarchal Ranking of Barriers in Implementation of Green Supply Chain Management-Case of Indian Petroleum Industry, World Academy of Science, Engineering and Technology,International Journal of Industrial and Manufacturing Engineering Vol:3, No:5, 2016.

- Mr. V. Balaji Rao, Supply Chain Network Design for Perishable Products in Developing Countries, World Academy of Science, Engineering and Technology,International Journal of Industrial and Manufacturing Engineering Vol:3, No:4, 2016.

- Mr. V. Balaji Rao, Analyzing Barriers for Implementing Green Supply Chain Management: Using DEMATEL approach for Petroleum Industry in India, Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, March 8-10.

- Vasanthakumar, C., Vinodh, S., & Vishal, A. W. Application of analytical network process for analysis of product design characteristics of lean remanufacturing system: a case study. Clean Technologies and Environmental Policy, 1-20.

Advancements of the Department

Department makes use of facilities set up by the University on personal enhancement and Development schemes such as career counseling, soft skill Development, career-path-identification, and orientation to well-being for its students.

Best Practices:

- Using video and simulations to impart learning

- Teaching by Industry practitioners

- Combination of field based training and classroom learning

- Supplementary Video lectures/Animations

- Field visits complimenting theory lectures

Upgrading Laboratories : Upgrading Image Processing Laboratory as Centre of Excellence

Course Pre-requisite

Academics – Schedule

| Activity Calendar for Industrial Engineering Department for 2016-2017 | |||

|---|---|---|---|

| Sr No. | TENTATIVE DATE | DAY | ACTIVITY |

| 1 | 16 TH AUGUST,2016 | TUESDAY | GENERAL BODY MEETING |

| 2 | 17 TH SEPTEMBER | SATURDAY | SEMINAR 1 |

| 3 | 12TH & 13TH NOVEMBER | SATURDAY-SUNDAY | WORKSHOP 1 |

| 4 | 3RD SEPTEMBER | SATURDAY | SEMINAR 2 |

| 5 | 10TH & 11TH DECEMBER | SATURDAY-SUNDAY | WORKSHOP 2 |

| 6 | 13TH AUGUST | SATURDAY | ASQ D1 |

| 7 | 27TH AUGUST | SATURDAY | ASQ D2 |

| 8 | 10TH SEPTEMBER | SATURDAY | ASQ D3 |

| 9 | 1ST OCTOBER | SATURDAY | ASQ D4 |

| 10 | 22ND OCTOBER | SATURDAY | ASQ D5 |

| 11 | 5TH NOVEMBER | SATURDAY | ASQ INDUSTRIAL VISIT (4TH YEAR) |

| 12 | 19TH NOVEMBER | SATURDAY | ASQ C1 |

| 13 | 3RD DECEMBER | SATURDAY | ASQ C2 |

| 14 | 17TH DECEMBER | SATURDAY | ASQ C3 |

| 15 | 7TH JANUARY,2017 | SATURDAY | ASQ C4 |

| 16 | 21ST JANUARY | SATURDAY | ASQ C5 |

| 17 | 4TH FEBRUARY | SATURDAY | ASQ INDUSTRIAL VISIT (3RD YEAR) |